Facilities

Growth facilities.

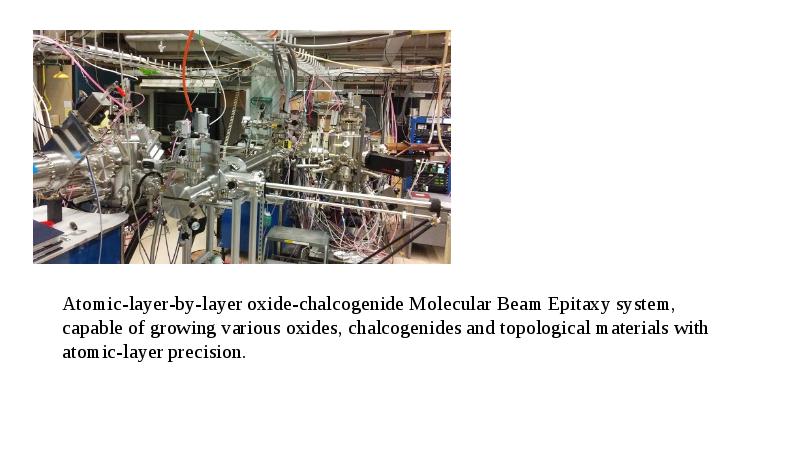

Three state-of-the Laser Molecular Beam Epitaxy (L-MBE1, 2 and 3) machines

have been developed in the Chakhalian's Laboratory for Artificial

Quantum Materials with the following unique capabilities:

- the stoichiometric and non-stoichiometric transfer of a materials composition from target to substrate

- practically free choice of background pressure during the fabrication using reactive process gases (e.g. all the systems can be operated with O2, ozone, CO2, N2 and Ar)

- highly non-equilibrium growth capable of kinetically stabilized metastable phases of materials unattainable via conventional 'slow' bulk synthesis or traditional all-oxide MBE.

In addition, Chakhalian's group has access to a conventional 4-cell all-oxide MBE to complement the LMBE growth effort.

During synthesis, the LMBE uses a high power UV pulsed laser beam (λ = 248 nm for KrF mixture, up to 800 mJ/pulse, 20ns long and up to 50 Hz pulse-rate) in order to ablate material from a target and transfer the ionized species to a substrate in the highly non-equilibrium way. The structural quality is monitored in-situ unique high pressure RHEED capable of aperating in 450 mTorr O2 pressure (Staib Instr.)

In-situ probes.

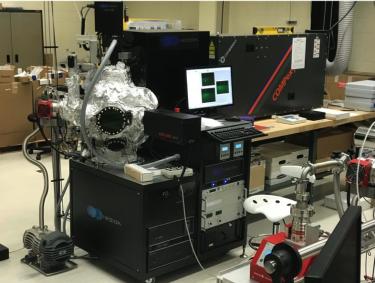

To ensure the availability of the layer-by-layer (LBL) growth and the

perfect stoichiometric quality of resulting quantum structures

Chakhalian's group maintain precise control over the structural quality

on the sub-unit cell scale with a ultra high-speed 2D-RHEED

imaging system. Proper chemical

composition of the films is crucial for the quality of materials.

To ensure desired stoichiometry during

the growth we developed an innovative in-situ X-ray spectroscopy (XRF)

approach operating in high oxygen pressure, which previously was available

only as a part of semiconductor thin film growth in

ultrahigh vacuum. The high pressure XRF system is capable to collect

X-ray spectra generated by electrons of the RHEED system, which ensure

that X-ray events originate only from the film surface.

One of the key components which have been recently installed into the XRF

detector is a specially

developed polymer window, which for the first time allows for low Z-elements

data collection including oxygen. Furthermore, the L-MBE2 is significantly

upgraded to incorporate the advanced in-situ

photoelectron spectroscopies such as Auger, EELS and XPS - capable of

operating in up to 10 mTorr of

oxide atmosphere; the innovative design is based on a high collection

efficiency double-stage

cylindrical analyzer DESA-150 recently developed in collaboration with STAIB

Instruments. This

implementation is unique. One of the unique features of L-MBE3 is its full

Omicron sample holder compatibility which allows to transfer samples between

various instruments without exposing their surface to ambient,

e.g. ARPES, STM, HREELS etc.

|

|

|